Whether you're involved in manufacturing or you manage industrial assets, ascertaining material integrity is a top priority. The quality of welding and other production processes can literally make or break your success.

Our efficient Laboratory services help you detect problems and find solutions in material welding, during production and exploitation. This provides asset management data which enables you to prevent damage and related cost resulting from material failure. From the sourcing and production phase, all the way to the end of the asset lifecycle, we help you monitor material integrity.

Contact us to order Laboratory services

Phone +370 615 17558

Email ab@inspekta.pro

NDT – Non-Destructive Testing

Our NDT laboratory serve a wide range of sectors around the Europe including power generation, oil and gas, petrochemical, engineering, fabrication, rail, marine and construction. Inspekta Lab’s NDT team of qualified, experienced technical specialists is dedicated to maintaining consistently high levels of expertise. All NDT technician are certificated according to EN ISO 9712 standard and Pressure Vessels Directive PED 2014/68/EU.

Our NDT technicians are equipped to apply a full range of techniques including:

- UT - Ultrasonic testing

- UTh – Ultrasonic thickness measurement

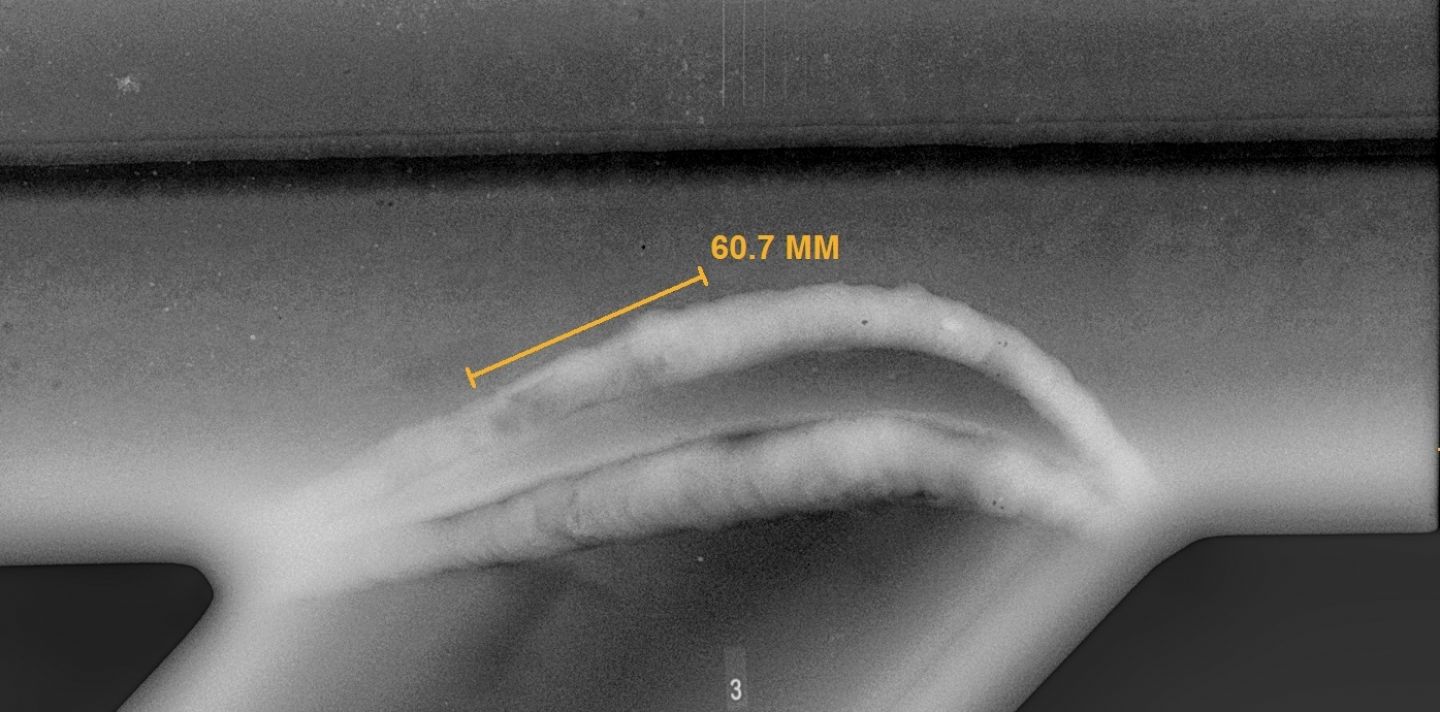

- RT – Radiographic testing

- PT – Dye penetrant inspection

- MT – Magnetic particle inspection

- VT – Visual testing

- LT – Leak testing

Level 3 certification enables us to offer the following technical and consulting services:

- Interpretation of codes, standards and other contractual documents that control the non-destructive testing method(s) as utilised by your company or project

- Guidance in selecting the method and technique required for a specific inspection

- Preparation and verification of the adequacy of procedures in the method certified

- Approval of non-destructive testing procedures and other NDT related work instructions for technical adequacy

- Training of NDT personnel

DT – Destructive Testing

Creating reliable constructions and products starts with the quality of the used base materials. The primary production process as well as subsequent machining, heat treatment and other operations influence material properties. Making sure that the used materials meet the applicable standards and requirements therefore plays a vital role in all industries.

Our specialisations:

- Qualification of welding procedures and welders according to EN ISO 15614 / EN ISO 9606-1 / ASME / AWS

- Testing of cutting-edge roughness, hardness and squareness according to EN 1090-2

- Failure analysis

Tests performed:

- Tensile tests

- Longitudinal tensile tests

- Transverse tensile tests

- Bend tests

- Hardness tests

- Charpy impact tests

- Macroscopic examination

LDAR – Leak Detection And Repair

The primary source of emissions of volatile organic compounds (VOC) from petroleum refineries and chemical manufacturing facilities are leaking equipment, such as valves, pumps, compressors and connectors. VOCs can pose a threat to workers and formulate ground-level ozone, a major component of smog. This secondary pollutant can cause or aggravate respiratory disease, particularly in children. In addition to workers at a facility, the surrounding community can be affected by long-term exposure to toxic air pollutants as a result of leaking equipment. Leaking VOCs will also contribute to higher running costs due to the loss of expensive products.

The US EPA specifies EPA Method 21 to detect VOC leaks from process equipment using portable VOC detection instrumentation. Inspekta Lab employs can help your company design and implement an effective LDAR program, allowing you to comply with EPA Method 21, local regulations and EN 15446.

Our monitoring working methodology

- Project preparation: planning, gathering unit information and structure, mapping streams on P&ID’s, database and LDAR module software setup.

- On-site activities: identification and monitoring of all potential leak sources, labelling of all leaking equipment with leak tag and first repair round.

- Data management and reporting: monitoring data input in LDAR database, data verification, automatic repair orders generation.

- Project handover: analysis & maintenance recommendations for the coming years, project data and reports, as well as digital project presentation.

AET – Acoustic Emission Testing

Technical malfunctions and failure caused by leakage, cracking, corrosion or defects pose serious risks for managers and operators of plants, pressure vessels and machines. Acoustic emission testing (AET) is a non-destructive test (NDT) method that reliably recognises impending problems and defects before they become serious.

Acoustic emission testing is not only ideal for localising cracks and leakage and for identifying corrosion and faults. It is also recommended for mandatory periodic technical inspections of pressure vessels and tanks in accordance with the National Regulation on Health and Safety in the Use of Work Equipment, and in particular as a special test method replacing visual examination within the scope of internal inspection.

Acoustic emission testing can generally be performed using the fluid stored in the tank. This has the advantage that pressure vessels or tanks need not be opened and drained prior to testing, so that AET is faster as well as more cost-effective and involves less organisational effort than conventional test methods.

PMI – Positive Material Identification

A rapid, non-destructive method, positive material identification (PMI) is performed on a wide range of components and assets, and provides a semi-quantitative chemical analysis. It is used for both material verification and identification.

The method is utilised for quality control and safety compliance, and is an integral part of both production and asset integrity management across many industries including oil and gas, power, chemical, pharmaceutical, construction and fabrication.

Positive material identification can prevent potential product failure in manufacturing. At oil and gas, power generation and pharmaceutical plants, pre-service and in-service inspection of critical components and welds with PMI can prevent breakdown and its costly consequences.

PMI can:

- Ensure products/components have been manufactured using the correct alloy

- Find potentially mixed-up alloys

- Identify if the wrong material has been used

- Ensure material conforms to the correct standard and specification

- Ensure welded components have used the correct filler material

Positive material identification is performed using either of the two techniques below:

- X-ray Fluorescence (XRF) analyser

- Optical Emission Spectroscopy (OES)

Our PMI inspectors can provide on-the-spot results followed by the certification of results in a written report. We also interpret and advise on the results.

PWHT – Post Weld Heat Treatment

Inspekta Lab offers post weld heat treatment (PWHT) to improve weld microstructure and reduce residual stresses developed during welding.

Inspekta Lab specialises in performing PWHT for the steel and metal fabrication industries including the construction of pressure vessels, pressure piping, storage tanks, buildings, bridges, offshore platforms, power plants, oil and gas refineries, and petrochemical plants.

There is often a mandatory requirement for PWHT due to compliance with welding codes and specifications on certain materials including but not limited to carbon steels, stainless/high alloy steels and work hardened steels. There may also be PWHT requirements based on the wall thickness of the parts being welded together.

PWHT reduces or redistributes the residual stress introduced by the welding process with a technique that involves heating, soaking and cooling the weldment/machined surface to controlled temperatures. This improves the properties of the weldment/machined surface. Other benefits of PWHT include:

- Improved ductility of the material

- Improved or reduced hardness

- Reduced risk of brittle fracture

- Relaxed thermal stress

- Removal of diffusible hydrogen

- Improved metallurgical structure

Inspekta Lab can perform PWHT at both our own premises and at our customers’ sites. Inspekta Lab can carry out PWHT at our customers’ sites at any offshore and onshore location utilizing our portable equipment. Our team of highly skilled and trained PWHT technicians ensures that all weldments/machined surfaces brought in for treatment will meet the specified welding code requirements and be fit for purpose.

By partnering with Inspekta Lab for PWHT, you will also benefit from our global services and experience. We can provide the non-destructive inspections that are normally required after PWHT is completed - including hardness testing, magnetic particle inspection and after stress radiography. Our metallurgical laboratories and experienced engineers with metallurgical backgrounds add to the wealth of knowledge and expertise needed to execute any critical PWHT while providing Total Quality Assurance.

RWC – Responsible Welding Coordinator

We can provide the services of a Responsible Welding Coordinator (RWC) to help you comply with the mandatory regulation of CE marking for structural steel.

CE marking for structural steel became mandatory for products sold on the EU construction market as of July 2014. Under the regulation, all companies that manufacture or supply structural steel for the EU are required to have a documented welding quality management system in place and will need to either employ or have access to a RWC.

The role of the RWC is to control and supervise all welding activities, and ensure the steel structures meet the adequate levels of mechanical resistance, stability, serviceability and durability.

EN 1090-2 sets out four execution classes for structural steel and they are based on the intended use of the structure and how critical it would be if it failed. The higher the execution class, the more stringent the quality criteria. Companies that undertake EXC 2, 3 and 4 welding activities require a RWC.

However, many companies may not need to employ or have the requirement for a full-time RWC, and would benefit from the potential cost savings of hiring a RWC only as and when required.

Inspekta Lab can supply the services of a RWC to oversee and control your welding activities.

The RWC will look at:

- Tender launches and catch onerous requirements of contracts

- Proofread contracts

- Visual inspection and non-destructive testing of welds

- Ensure personnel work to procedures and are suitably qualified

- Materials verification

With our RWC services, you can be confident that you are compliant with the 2014 mandatory regulation of CE marking for structural steel.

QA/QC – Quality Assurance and Quality Control

Inspekta Lab quality assurance/quality control (QA/QC) services help our clients to define and qualify their QA testing programs, and ensure that their products meet all necessary industry, manufacturer, and customer standards.

Not only do newly-manufactured components and materials of every size and shape need to conform to multiple manufacturer, contractual, and industry regulatory standards, the processes used in the manufacturing process must be in regulatory compliance as well.

Inspekta Lab offers quality assurance (QA) consulting and quality control (QC) lab testing services throughout the manufacturing product lifecycle.

Inspekta Lab works with our clients to devise procedures and systems that prevent defects caused in the manufacturing process and ensure that all deliverables are manufactured uniformly and in compliance with regulatory and customer requirements.

Our QA services include:

- Auditing

- Operative Process and Method Assurance

- Procedure Qualification

- Process Optimization

- Procurement Quality Assurance

- Supplier Evaluation

Inspections

- Inspections of critical safety equipment

- Assessment of conformity of potentially hazardous installations

- Other services for industrial companies

Certification

- Certification of welders

- Certification of construction products and welding procedures

- Preparation of national technical assessments

- Certification of management systems

- Electrical energy engineering personnel certification according national according to national certification scheme approved by VERT.

Engineering services for buildings and the construction industry

- Technical supervision of construction of buildings

- Technical inspections of buildings

- Technical audits of buildings

- Energy audits